I’ve seen a lot of sweet uses of epoxy tricking out a deck with exposed wiring, EL wire, etc, but what I’m wondering is if epoxy ever cracks when the board flexes. I haven’t worked with epoxy that much so maybe I’m ignorant to it’s properties, but I would think since it’s very hard, it would crack as soon as I bounced on my board. Has this ever happened to anybody and if so, any tips for ensuring it won’t happen? I’m planning on modding a bamboo Vanguard clone from DIYeBoard.

There’s different types of epoxies with different properties.

Cheap resin epoxy tends to be brittle, laminating epoxy tends to be a lot more flexible and probably more suitable for an application like this assuming you’re not dealing with a lot of thickness.

If you are dealing with a lot of thickness its probably better to use a slower cure, or possibly find a casting resin.

Laminating epoxy is the same stuff you’d use for glassing a board, so like West Systems Epoxy.

I see. Full disclosure, I’m planning on routing a channel along the edge of the deck, embedding wires, and then covering in epoxy/resin so I’d imagine it would be pretty thick to fill in a 1/4in or 1/8in channel. Maybe I should just use silicone. Silicone doesn’t seem very durable though (especially if it’s on the edge of my board). Thanks for the suggestions? Any others?

I wouldn’t use silicone, its definitely not very durable.

Reading a little bit it seems there shouldn’t be any problems with that sort of thickness.

You could make control joints if you are worried about it. Prolly every 6 inches or so would work.

I think modeling clay or something similar would probably work well to keep it neat. Could get artsy and do it in black, for a contrasting color.

Make the silicone come up higher than the deck, then cut it off flush with a razor blade after it cures.

Then epoxy your wire channels afterwards.

What do you need epoxy on the Vanguard for? I’m guessing to cover the routed channels to connect the ESC compartment with the battery enclosure.

If this is the case, you don’t need to use epoxy at all, just route the channels to the exact wire diameter and cover it with grip tape, it’ll be invisible, you will thank me latter when you need to replace/change those wires in the future.

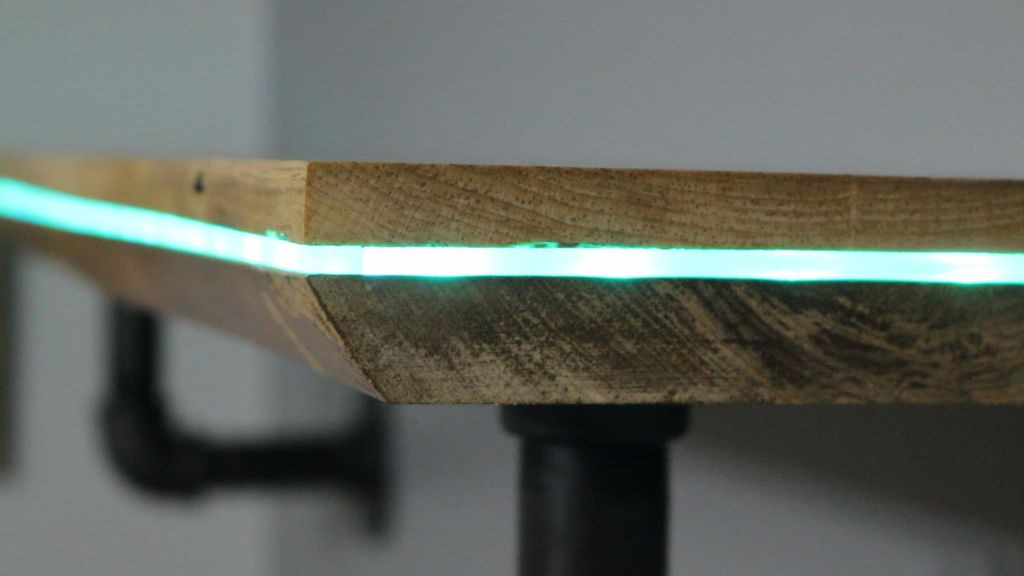

I actually want to route a groove along the entire edge of the board wide enough to cram an LED strip inside, then seal it back up with some kind of epoxy/resin/silicone. That way I can have LED edge/under lighting without the ugly PCB strip glued to the bottom of my board. I want it to be seamless, sealed, and invisible when not in use. I was trying to keep it on the DL because I wanted to be the first to do this, but oh well.  Something similar to this shelf:

Something similar to this shelf:

Most likely, I’ll have to sand off the finish on the board so I can apply some kind of design to the raw wood anyway, so sanding epoxy down flush shouldn’t be too bad. So now that my plans are all out in the open, what say you? Can you think of any better ways to embed LEDs in the board edge itself than what I’ve come up with? Has someone beaten me to the chase already?

Well I’m not a fan of led strips on a esk8, even if they are hidden on the side

Yeah, I’d agree that most of the time slapping a bunch of lights on something can make it look like a kid’s tacky light up shoe and I hate when something doesn’t look stock, but I also think you can do lighting right if you give it some thought and keep it super subtle. That’s what I’m going for here.

My concern here is that all LED strips I know of are fairly wide, about a cm.

There enough thickness of a vanguard to cope with that?

My first thought was to see how much I could trim off either side of the LED strip without compromising its function. I also thought about folding the PCB on either side of the LED in order to shrink its profile. Another option could be to route in at an angle effectively increasing the depth/width I could route at and pointing the LEDs more toward the ground. I could also always just route out the bottom of the board (instead of the edge) so the strips are facing the ground. Not as cool in my opinion but it might work better (especially for flexing).

My main concern is that if I have a thick layer of epoxy resin on the circumference of the board, it might either dramatically reduce the flex or crack. I might have to test out several different kinds.

Look at all that extra PCB on either side. If I can’t trim it off, I might be able to fold it backwards.

I like this one. With a V groove the light bounding off the angle should make it a lot more diffused when it comes out the side. One thing LED strips can struggle with is diffusion.

You could even paint the inside of the groove white to reflect light better, though obv. it would have to be compatible with the epoxy you use later.

I did also manage to find this:

3.5mm wide strips, so thin strips are made… But this seller is pretty expensive.

My concern with an angled light would then be if the strips are flexible enough to be mounted at an angle and also bend around the perimeter. Thats probably something you’ll have to test.

We’re totally on the same page with the extra thin LED strips. Blinkinlabs sells RGB ones that are 4mm thin: https://shop.blinkinlabs.com/products/4mm-wide-led-strip-white

Yeah, I’ll need to experiment with different mounting angles to see what diffuses it best. That’s another thing I hate about most longboards with LED strips duck taped to them: they’re not diffused! I thought about mixing in a tiny bit of glow-in-dark powder to the epoxy resin to see what that would look like as well. There’s so many different directions you could go with this.

Another option, since you’re only looking for sublte lighting might me EL Wire.

Yeah, I thought about EL wire, but you can’t animate it. When I say subtle, I mostly mean hidden in such a way that it looks stock.