Yes, but current wise it’s the same as other spark switches, just two MOSFETs without any heatsinks so no more than 40A could be pulled continuously.

Well he’s working on that MoreAmpsSheild that apparently handles 240A, and does a bunch of other neat stuff you’d probably want if you were running that much current.

Still, get the feeling some people would still like to forgo the complexity of a BMS. So a good switch, is still a good idea.

No matter the quantity it’s impossible to go that low. Seriously have a look at the BOM.

On his more amps shield I do not saw any more mosfets to handle more current so I don’t know how he is going to get more current from that PCB…

Plus my switch uses the same logic as his board for switching power, its kind the best solution you can get. Just I use more powerful mosfets and mcu

It would seem that there aren’t more transistors on the board, but rather more parallel/lower resistance shunts so they can measure currents up to 240 A, without melting their current shunt resistors. Or so I would understand from his quoted sentence and the linked pictures in the reply.

I also have to wonder with @Kug3lis how they plan to keep their transistors from escaping into the atmosphere at such high currents.

That’s why I am really curious how they handle the current, because current does not divide equally between paths so I am bit sceptical…

Plus the IRFS7530 has some high heat output at that current…

250A through 0.0014 Ohm dissipates 87.5W of power, P = I^2 * R. 87.5W x 313 K/W gives a junction rise above ambient of 27387 K, or 3500C…  (can be really wrong calculation as I don’t remember correct formulas) and it’s only for single mosfet.

(can be really wrong calculation as I don’t remember correct formulas) and it’s only for single mosfet.

Where? and in what quantity? That deal sounds like a shenzen bait and switch to me.

That’s what i was thinking. Maybe under $100 is possible… somewhere…

why is it rated for a 100amp fuse then? I run twin IRFS7730 mosfets at well over 50 amps all the time and they’re fine. They seem to start having issues right around 60 amps under 200+ pound loads and the speeds associated with those amps, which for my weight class is above 40mph. Are 7530s that much different?

The load of skateboard is not continues, as I am saying for continues load max 40A, but for longboard 50-60A should be enough but not 250A as he states in his message…

On my board I will just put several SOT227B style mosfets on big ass aluminium plate and will not have any problem even with 200A

Also, I’d like to give you some constructive input on your anti-spark switch design.

You really lose the pro of using more powerful MOSFETs if you use them in the fully blocking setup, because you actually end with more dissipated power overall compared to the 2 parallel IRFS7530s in one direction. Your overall Rds(on) will be higher due to the current having to run through 2 silicon dies in series (even in the parallel version). Now if you plan on making a heatsink for it, then you might make up for the increased heat production by being able to pull the heat away more effectively due to more surface area to move the heat off of the packages to the heatsink, but overall wouldn’t it still run hotter, at least power dissipation wise?

IMO, MCU seems a bit overkill. I (personal opinion) believe that most people would want their e-switch to be as simple as possible. AKA it’s either on or off. They want to disconnect their battery from their motor controller by holding a switch down for a couple of seconds and connect it back by doing the same again. I doubt they want to start faffing about with firmware and flashing it to the MCU. How are they supposed to flash the firmware again? are you going put a header to the board, which they can use? How many people have the programmers and the know-how needed to do this? Are you going to flash every board yourself you plan to sell? I really don’t think the MCU is the best choice in this case, but rather more simple logic gate based one, which’s output is toggled by holding down a momentary pushbutton.

Just my two cents.

I use them in the fully blocking way just to prevent burning the battery with a current running in from VESC or etc then the board is off. Either way, its how normal BMS looks, this whole switch is just a part of professional grade BMS just the switching part, the same design is in jtag version of BMS too. The MCU will be one time programmed because I saw saying that vibrations can make button switch and turn off the board while riding if anyone wants it can be a simple toggle switch. You will not need to program it or do anything related to it.

On the other note about fully blocking mode is like to prevent inbound current to battery then the battery is fully charged, or etc. It would work partially as BMS without balancing. Turn off the load then minimum voltage is reached or etc.

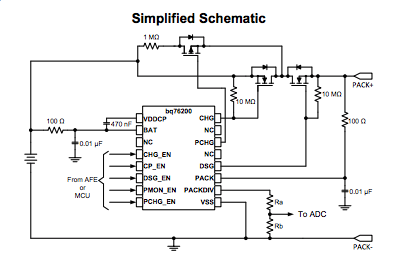

Yeah I just opened and saw he is using two different paths. My bad but if you look in other reference design of bms and etc you will see

I would also then bring into question about how useful the fully blocking arrangement is still going to be, because I assume that most(?) esk8 motor controllers are VESC based, in which you can set the max DC bus voltage limit, so you can disable regen brakes if your battery voltage rises too much, making the fully blocking setup needless.

Then in the case that you’re going downhill braking and the VESC cuts out, because the DC bus voltage rises too high. then you’re still going to be in some trouble, because now you can’t brake, your speed is increasing, your motor is producing higher BEMF and your MOSFET Vdss is still 60V at which point it will experience breakdown and the current will then go through it and then through the body diode of the other MOSFET into the battery, again making the fully blocking setup seem a bit… useless.

We need to dump energy somewhere if we want to slow down. So in a dangerous scenario as pictured above, I would say that it’s better to ruin a battery, then be out of control.

I mean yes, I was talking more case then power is switched and you push the board and then motor acts as generator and leaks current  But I mean if there is a need for simple switch without blocking I can change the design, I just wanted to make simple fully disconnect switch on positive path not negative and only half disconnecting. The whole closing charging and etc was just an Idea what I can do with MCU in place. I am doing this module for the community, not for myself so I am up for suggestions and ideas.

But I mean if there is a need for simple switch without blocking I can change the design, I just wanted to make simple fully disconnect switch on positive path not negative and only half disconnecting. The whole closing charging and etc was just an Idea what I can do with MCU in place. I am doing this module for the community, not for myself so I am up for suggestions and ideas.

I fully agree that having the N-channel FET on the ground side is not ideal and I would much rather see the e-switch being a high-side solution. I have also done some idea work on how to make it high-side, higher current with simple IC solution (no programmables).

What I would like to know is, what’s the failure mode of the Vedder anti-spark switches, because many people seem to be breaking them, but I want to know why they are breaking, so it could be remedied if I or somebody else were to make a high-side e-switch.

For the high side, you need only high side MOSFET driver IC and that’s all… Nothing special, I can adapt this design to not be fully blocking, and be only one side and other side diode will leak current pack to pack, the MCU can be replaced with simple toggle switch if that’s the case and that’s all…

I seem to have missed this discussion and the questions that were raised here. Ill elaborate on some points shortly, for now let me just state that the MoreAmpsShield is not capable of switching the high currents, it is just capable of measuring (which I still have to validate trough, I^2 is a bitch) it. Switching happens trough a relay:

Eventually ill make it solid state, fully blocking with a shitload of FET’s and a heat sink, this will also be a real challenge  .

.