Hello everyone, My name is Andrew. I am currently a 1st year Mechanical Engineering student at the University of California, Santa Barbara. Most of the students here commute on bikes and longboards, and I thought it would be very convenient to have an electric skateboard to get around the campus. The bigger focus of this build is to create a project that would look good on my resume, and to a great conversation starter. I planned on building it over the summer so I did some intensive research in the past week or so. I understand that to build a decent board isn’t going to be cheap, but I am somewhat going to treat this as an investment for future opportunities. So my budget is set to around $1000.

The following are the parts I have decided to use.

From @torqueboards ($528.97 plus shipping = ~$550?): Dual Motor Electric Skateboard Kit, which includes: (2) 6355 190KV (I am assuming is the 6355 190KV at 2500W motor) (2) VESC (I think is TORQUE ESC VESC ® BLDC Electronic Speed Controller) (1) Male to Male Connector (1) VESC Canbus Connector (1) Dual VESC XT90 Parallel Connectors *the assumptions were made based on the prices, @torqueboards please let me know if I am wrong Longboard Bearings 8mm 2x 36T KEGEL Pulley Combo Kit Looking to get the 13T motor pulley TorqueBoards 2.4ghz Nano Remote Controller

From Amazon ($95): Orangatang Kegel 80mm 80A Caliber Trucks Cal II 50°

From Hobby King (~$140): 4x Turnigy 5000mAh 4S 25C Lipo Pack Planning to put 2 in series and 2 in parallel to get 8S 10000mAh

For the motor mounts, I have some pretty good machining skills, so I think I will be able to machine them myself on a mill. (I might need some drawings)

As for the deck, I am looking for a deck that has similar concave (and maybe flex) to the Vanguard (the Vanguard itself is wayy to expensive), but I am not really in a rush to decide on a deck because I want to see how much space I really need to fit all the stuff underneath it. Decks that I am looking at: Madrid 2017 Weezer Longboard Skateboard Deck w/ Grip ($104.95) Sector 9 2017 Mini Fractal Longboard Skateboard Deck w/ Grip ($93.95) Sector 9 Lookout Longboard Skateboard Deck w/ Grip ($84.95)

And the enclosure, I was planning on 3D printing a two part enclosure after finding out how much space I need.

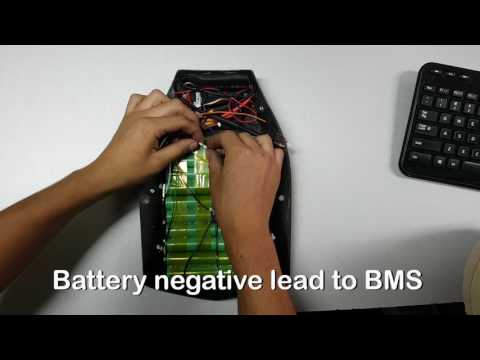

None of this is 100% set, hence the reason I am reaching out to you guys to get feedback. I want to build something that is decent quality and would at least last me through 4 years of college. My visions for this board is to get around 22 - 25 mph top speed (not crazy fast but decent), and get around 12 - 15 mile range. It would also be nice if I could get a BMS connected to my batteries so I wouldn’t have to worry about the balance charging thing.

Like I said earlier, I want this build to be a project that I could put on my resume. Which means the more DIY I do, the better I can demonstrate my skills to future employers. I have seen many people on this forum who built their own battery pack, but I think for me that might be a tad bit advanced. But should I custom make my own wheel pulleys rather than buying them?

PLEASE let me know what you guys think about what I have so far, what I need, and the concerns I have. THANK YOU for reading all this haha.

Im excited to see how your battery comes out!!

Be sure to post your specs when your finished discharging!

Have you busted out any hills with the naked vanguard yet?

Im excited to see how your battery comes out!!

Be sure to post your specs when your finished discharging!

Have you busted out any hills with the naked vanguard yet?