Yes man. And also nylon carbon fiber is very very good, you should try!

Im printing nylon carbon at 260 Celsius and hot hot bed at 110°

Glued bed too

And skirt brim of 30 outlines

It’s HARD to print yes

@mccloed is our printmaster. He brought a pulley over that was made out of the Nylon carbon and it seems really nice. He said the size increases though, so the finished product wasn’t actually htd5.

nah, im not with you on this on here.

-

While PETG is pretty awesome, its also rather “explosive”. meaning it wont realy bend, but rather shatters into thousends of pieces. thats why PETG is not the greatest merterial parts which are under mechanical stress.

-

PLA is OK for everything which doesnt have to move. like cases or covers. maybe also for the large pulley but definatly not for the small one. but then again, PLA deteriorates rather fast and bercomes very brittle.

-

nylon has a certain amount of flex to them and thats why they are so great for mechanical parts.

also, the hydroscopic part doesnt realyy matter. it not like they are going to absorb their weight in water. it jsut sux for printing. nearly Every filament out there is hydroscopic, even PETG. but once printed, it doesnt matter.

I have had experiance with nylon, but I havent had anything fail due to moisture absorbtion. I have however noticed a difference in the materials properties over time which meant the part wasnt in its intended use case and got remade in PETG.

Im not saying Ny isnt a good material, Im just relaying information which I and many others use in industrial aplications as a change in properties tends to lead to catastrophic faliure.

I wouldn’t have thought you could print a motor mount or motor pulley, I’ve seen a couple of motor mounts on here i think, but they were very bulky and were very much in the experimenting phase.

printed pulleys work great with PETG, Nylon or ABS. Mounts however usualy need some sort of reinforcement like insert metal rods. at least the PETG ones. A nylon mount might be a tad bit to flexiable as mount but i never tried that.

Can confirm, and gets worse with time.

Over extruded or something like?

I’m using Nylon mount on Mountainboard, with 20mm thickness, no problems

yeah, same here. I’ve been using sintered nylon wheel pulleys for well over a year now with zero issues. They perform better than even aluminum in my opinion. They last just as long and don’t shred belts every time a rock deforms a tooth.

i think he’s talking about regular 3D printers though and not industrial scale sintering. Running wheel pulleys from a desktop 3D printer probably wouldn’t be the best idea.

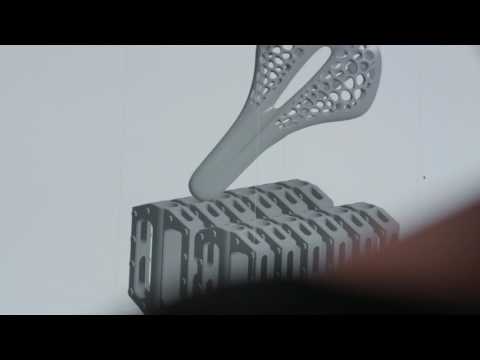

pics and STL please ![]()

nope, all fine. works like a charm if you print it properly.

What printer are you running by the way?

Hit it right on the head. Sintered parts are chemically much more resistant. if you have the machine, your golden ( and IM jelous ![]() )

)

I’ve built my own black widow from Tevo

Titan extruder

Pics coming soon, sharing the STL it’s a problem for me since I’m selling them.

I’m printing with desktop 3d printer, nothing more than a fdm printer

I have been running 3D printed pulleys for hundreds of miles with very little sign of wear. They are printed on a desktop Flashforge creator. I’ve been using cheap nylon from Microcenter http://www.microcenter.com/product/485160/175mm_Natural_Nylon_3d_Printer_Filament_-05kg_Spool(11_lbs)

Unfortunately, this is the only color they have. Kinda lame. I’ve had a couple pulleys printed by shapeways and they are good in the sintered nylon but they are no better than what I can print except for the aesthetics.

I’ve had a couple pulleys printed by shapeways and they are good in the sintered nylon but they are no better than what I can print except for the aesthetics.