How can i get all of my screws to stay tight no matter how much locktite and torque I put into it they always come undone. Also how can i make my esk8 last more the 2 days with out a problem. I love it but im about ready to throw this thing in the trash.

I think you have a bad batch of locktite. Normally, if you properly clean your screws and screwholes before applying, there will nothing get loose.

@Gabriel_Robinson are you letting your locktite cure? It takes time before it is fully effective.

We’d need a lot more information or a build thread to help you increase the reliability of your build. Can you share more?

what specifically is loosening? Show us some pics and explain your setup.

I fought non-stop with a APS setup on Paris 195’s way back… PITA to keep it from rotating and hitting the road when braking. Board was stolen before i could fix. I stick to keyed mounts now on Caliber II’s for this reason.

What type of locktite are you using. green,blue,or red?

also pictures of your setup would also be helpful.

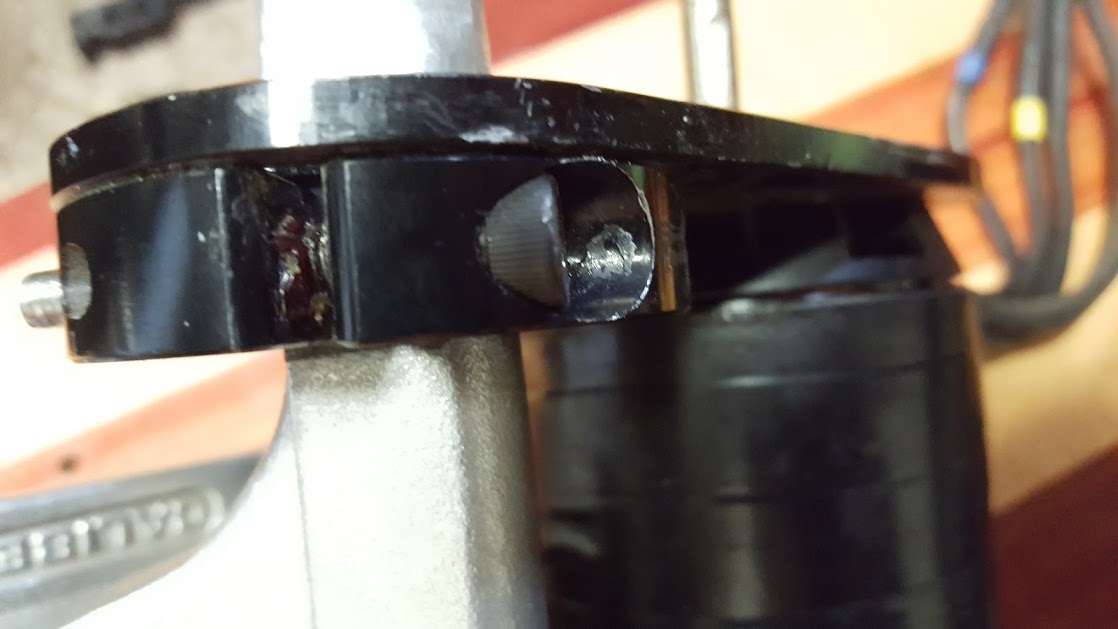

@notepad @flatsp0t @treenutter @sl33py I am using caliber II Trucks with the Torque board mount and red locktite

Wow - i’ve used these and never had an issue… with just the blue loctite.

The main screw is loosening, or the grub screw?

I had to add two soda can shims before mine stayed in place.

Ill try that!

The grub screws. Which then allows it to slide side to side just the smallest amount

Have you try to switch the trucks (with the one in front), since they are cast they might have a slight difference in the overall circumference.

I also had this problem with a different mount and bought caliber I insted, since they have a bit more meat…

good procedure would be to take off the mount. undo any bolts that have locktite, then give all the parts a acetone bath, followed by isopropyl alcohol, then followed by ethanol, and lastly a bath of water.

This should remove every possible contaminant that would inhibit the locktite to not cure properly. Remember, Red is designed so that only heating the parts will allow the locktite to be removed, and needs a full 24 hours to set. So it really shouldn’t be failing from normal use.

If none of that works, repeat the cleaning steps and return/refund your locktite because Red should never ever fail you under these circumstances.

Should i also put the mount in acetone to clean the threads?

yes, anything that has come into contact with the material would need to be cleaned. if you have a ultra sonic cleaner it would go easier, but an old toothbrush is also a suitable replacement!

Could I use gasoline and a tooth brush (im out acetone

that could also work, but acetone would be better as its less likely to leave behind contaminants. remember, acetone is nail polish remover, so if you have that you have acetone.

I also have been using TB’s V4 mounts for close to a year now and they never come loose. I would not use Red loctite on a dual setup because you have to be able to remove the motor plate incase you need to remove a motor. I use blue loctite and it is plenty enough. Any oil or grease will void the loctite. Acetone is good for removing oil and grease. A tap and die works well to clean the threads of gunk before washing them with acetone. I did not use grub screws on the truck clamps. I just used shrink wrap between the clamp and truck. That still didn’t get it tight enough at first so then I remounted them by taking the main bolt out and spreading the clamp by forcing a wedge into the split of the clamp so that I could get more shrink wrap in between the clamp and truck. Then I put a C-clamp on the truck clamp and compressed it as tight as I could with the C-clamp. Then I put the bolt back in and tightened it as tight as I could without stripping it. Then I removed the C-clamp and the truck clamp as been rock solid on the hanger ever since.

P.S. Acetone is not very expensive and you can get it at just about any hardware or paint supply store. Be careful though, it is very flammable and if it gets on your skin, it can cause dermatitis.

So you still are not using grub screws and it stays tight.

On all my motor mount screws I put a tiny washer in between the screw head and the mount. This prevents the screw head from digging into the metal (typically a softer aluminum) giving you a nice snug fit. Blue locktite would loosen for me overtime (I ride some rough streets) but since using the red I have had no problem.

No grub screws. In fact my clamps don’t even have holes for grub screws. That came on a later version. The trick was that I had to spread the clamp in order to get enough shim under it so that it would tighten. And I also use small flat washers on the motor plate screws. That helps to get them tighter and keeps them from gouging into the aluminum. As @jeff mentioned. I won’t use red loctite because I am running dual motors and I like to remove them periodically for cleaning and to replace their bearings. So I have to be able to remove at least one motor plate and I don’t want to have to use a torch on it.