Janux hubs are machined from solid rounds of Acetal Delrin, not 3d printed. Hubs were designed to fit the following 6x2” pneumatic tires: https://www.aliexpress.com/item/6X2-tyre-6-Inch-Scooter-Tire-Inner-Tube-Set-Electric-Scooter-Wheel-Chair-Truck-Electric/32840513077.html?spm=a2g0s.9042311.0.0.czdUJy. I can also modify them to your specs.

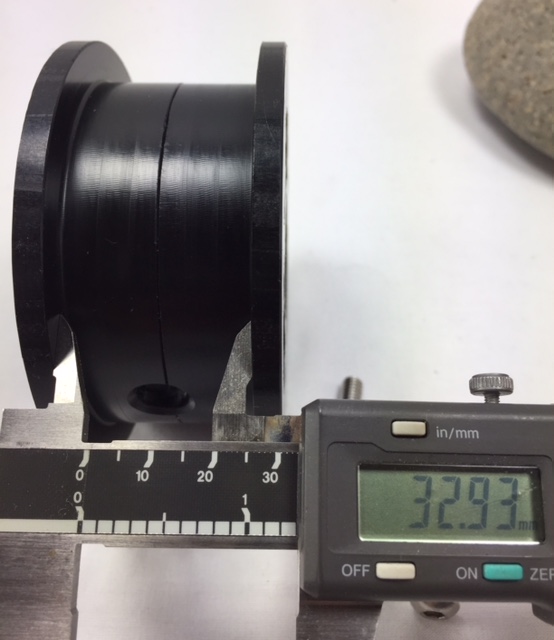

Hubs come in 2 halves, bolt together with 3 x M6 hex caps. Hub diameter is ~74mm, rim diameter ~90.5mm, rim (lip or bead) is 5mm thick, overall thickness ~43mm. Wheel spacers are replaced with bearings for smooth running and to provide extra support for the entire thickness of hub. Each hub is supported by 4 bearings - two bearings are on the outside facings and two on the hub interior, replacing wheel spacer. Hub is practically riding along the entire length of 4 bearings.

Please specify the truck when ordering, ie MBS, Trampa MTB Spring, Trampa Carve,…

- Set of 4 hubs - $150 (specify truck)

- Set of 16 bearings - $16

- Customizable POM pulleys - $ according to spec (44 - 72t)

- US shipping $8, International shipping $25

What is Acetal? Acetal resins, aka POM (polyoxymethylene) or acetal Delrin are engineering thermoplastics based on formaldehyde polymerization technology. These highly crystalline resins are strong, rigid and have a low coefficient of friction against metals, acetals and other plastics. They are creep resistant so they are good for parts where dimensional stability is important.

POM have high tensile strength, stiffness, resilience, fatigue endurance and toughness. They have high resistance to organic solvents, excellent dimensional stability, a low coefficient of friction and outstanding abrasion resistance among thermoplastics. Acetals’ resistance to creep is excellent. Moisture, lubricants and solvents including gasoline and gasohol have little effect on this property, which is important in parts incorporating self-threading screws or interference fits.

Solid round of 4" x 12" Acetal Delrin

Stock sliced into 1" thick pucks, machined flat and true on both faces, and individual cnc’ed

Inner and outer halves

Wheel spacer replaced with dual inner bearings

Quad bearings run entire length of hub

Customizable pulleys 44-72t

Available in black and white

Outer face with 6 x 10-24 hex bolt pulleys

Inner face, note: the 4 bearings along the hub axle

Easy installation of hub to tire

Insert inner half to opening

Mate outer half with 3 M6 bolts