Hi guys just thought I might as well create a thread for a personal project for the hell of it.

Quick thing before the log: This is not under innovations as I know gear drives have already been designed for the E-mtb scene but this has been an on and off idea which I am finalising into a working prototype.

@moon has already designed a great modular gear drive alongside pioneers such as @Nowind but my design is purely for myself and my enjoyment in this hobby. I do, however, aim to force the costs of these drives as low as possible to see what I can create compared to relative competition.

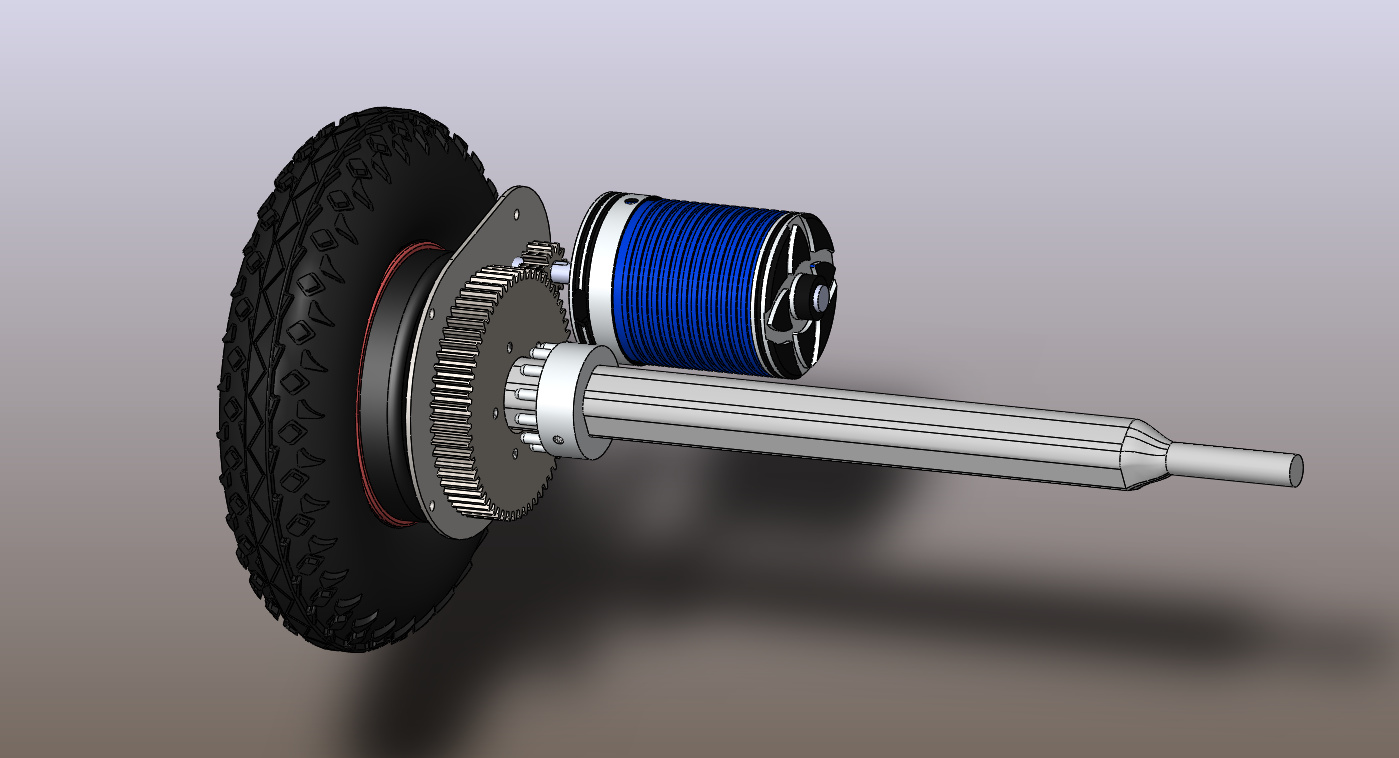

Currently the design shown below has quite a few potential problems that I am currently addressing such as the pinion gear being based off an existing design for sale online with a limited 11mm face width. In future designs I will ensure the gears are at least 15mm in width. Another problem is clearance with the modular clamp attachment being placed outside the mount and enclosure which only leaves a few mm between the clamp and the model of the SK8 BLDC motor. This design will fit 63mm motors although I kind want to exceed this for all you 80mm APS enthusiasts and the likes.

Gears

The design showcases a 1:5 reduction using 1:5 MOD spur gears (a 12t pinion)

At the moment material choice for my gears is up in the air and is restricted to what I can source relative to my budget and machinery access. I am a student so have not built up too much inventory in tools, equipment etc. A few of you may notice the teeth are not straight but don’t panic this can all change.

Enclosure

I love my 3D printing so I will definitely experiment via this direction. As for future-proof aluminium constructions this maybe a possibility depending on sourcing in my local area without getting ripped off. I have contacts who can do a nasty good deal on possibly ASA 3D printing and even Nylon so who knows what I might try.

Hub adapter and modular clamp

Both parts will be 3D printed during the modelling stage and then I will hopefully outsource a skilled CNCist or at least their equipment to manufacture at least the clamp out of aluminium, again depending how far I take this project.

Compatibility

To all you trampa fanboys and the likes, this build is for my new MBS board (cheers @Chrisjarram) so is currently being designed for the Matrix 2 pro trucks and Rockstar pro hubs but if this turns out successful I may test other hangers and hubs etc. The modular clamps allows rotation of the drive in 12 degree increments as a clearance solution.

PSA: The matrix 2 pro truck hanger profile is so dumb.

Seal

This design incorporates a v-ring that is inset slightly into the hub attachment to seal off the drive from the environment. No bearings are used in this design at the moment.

CONCLUSION

- No heavy roasts in the comments.

- Give me as much criticism as possible

- Do throw ideas my way as its now or never at this stage

- This design hasn’t been made pretty yet so all the aesthetic connoisseurs can give me some inspiration on colours and inlays for the enclosure etc.

Renders will come soon once I access the stupid full version of solidworks at my school.

If this initial post turns out well I might follow it up and potentially release the designs to everybody for free with a parts list but I will most likely test the crap out of my future prototypes before releasing anything

Cheers again for the good community vibes