Make sure everything is clean (alcohol). all surfaces nice and flat. Try varying pressure. Low pressure actually makes stroger welds.

I am afraid your lipo will not be enough.

@moderators could you please reset the edit count of the first post? People keep failing on the lipo choice. This thread is too big to read. Please allow me to edit again the first post.

Yes, that’s true but be SUPER careful with that. A little pressure less than needed is a guaranteed hole. During my initial tests i pierced both nickel and can. I am glad It was a dud cell.

I did a common flat build, 10s3p 30q with bms on top. 0.2 nickel

shared port bms(model S)

I will upload a video when edited. Hope it helps

no issue on 2x 4S 45C 4500mAh batteries here. Actually think I’m down at 4ms and 2x.

Hmm, so you’re using 4S instead of 3S for 0.2mm nickel-to-nickel?

yeh I don’t have any 3S that was suitable so I use two 4S in paralelle so it becomes a 9000mAh 45C.

The lipo is brand new. The points are polished and have 2mm gap point-to-point. I feel like I somehow have an underpowered welder. I don’t see how you can get welds with 8ms x2 when I can’t with 16ms x6. That’s like 6x more energy put in.

Is anyone who already has this welder willing to test mine? I will ship it to you on my dime with some of my 0.2mm strips.

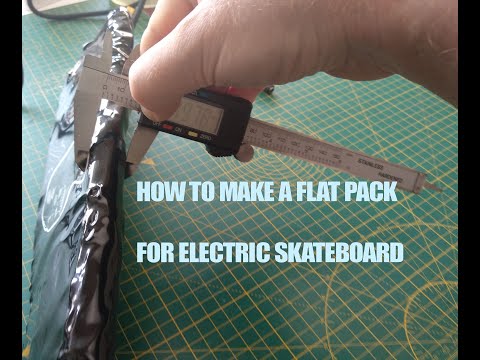

OK, first battery build. Using the boss spot welder.

I spent some time playing with the welder and a razor knife to test the settings and arrive at a decent weld.

Right now I’m using 10ms, 2 pulses 3ms apart

These settings gave me good welds on the razor knife.

Results:

The welds look anemic to me. I think I’m going to up the time to 12 or 14ms and see how the next set goes.

Any advice would be appreciated!

I would up it a bit, but it looks pretty good. Maybe 12

yep. did that. looking better, but weld is slightly discolored.

i guess its ok. this first pack looks like shit. all out of alignment. thats what i get for just diving in and not planning ahead!

looks like a set of bad teeth. >:(

Love the pcb!! Finishing season 3 tonight

oh, didn’t even think about welding onto the pcb, i thought it was meant to be soldered.

are the welds onto the copper sheets holding up ok?

thats gold plated copper! ENIG finish. and they seem to be ok. i did 3 welds per pad, might do more for insurance.

fused.

1 down, 11 to go!

looks good.

i’m totally going to copy you and then call it my idea…

Doesn’t it feel crazy though, to get cells that can do 20a, and that huge copper bus bar, then put that tiny relatively high resistance wire there? I’ve yet to come to terms with this.

Looking great!

love that pack !

where find this PCB ad the “fuse filament” ?

(any dedicated thread is welcome  )

)