Very nice! I wonder what their dyno looks like!

And also someone in a Facebook group pointed it that at the bottom it says 5025/5045, those are just factory part numbers.

looks like stator size. actually more accurate than can size…![]()

That could be it.

Do you think you can get this motor on the GB? And some data… not sure if it’s the same factory

Ive been curious about it for a while! It has double the poles. Kv is perfect for 8s-10s

That’s not a good motor if you want to use it together with a VESC. Because the ERPM would go as high as 120000. And that is by far above the recommended max of 60000.

+1 for 12s data. Can you request that? Probably 46-47 volts - fully charged with some voltage drop.

Really interesting information.

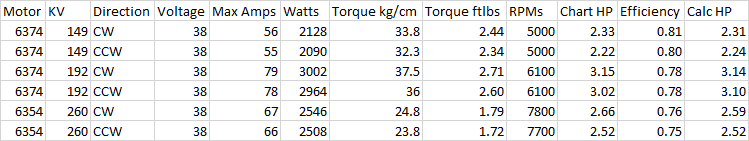

Motors are running at 80% efficiency at full load. Motors are putting out 2-3hp after efficiency losses! Running clockwise is slightly more efficient, but not significant.

[quote=“wmj259, post:1, topic:19721, full:true”]

Enjoy. 6374 149KV

[/quote]It is interesting to see a value above 6000 RPM. At 38V and 149kV, you would think the max speed would be ~5600 RPM

So perhaps a motor’s kV is a function of nominal speed under load, not an unloaded maximum speed. If you look at the max and min of the purple line above, 5600 RPM is right in the middle

Side note: Did you ever hear back from the company regarding charts for 12S?

I haven’t had a reply about that topic. I will ask again, but I think they used motors from my order to perform these. I will check again.

Even if they had charts of any motor at two different voltages, we could see if/how the voltage affects other parameters

I’m researching for my own build and am actually desperate for this info for my own build!

Are there really no speed-torque curves for motors at different voltages?

These look like great datapoints but i’m at a loss how to use them.

I have the 6374-149, and I want to run it at 1000rpm. It doesn’t look good for me.

I need a ton of torque, it’s for a marine motor and i have option of many propellers. I want to get 2hp if I can, but how do I determine torque and current at 1000rpm? This dyno appears to be running flat out, and then ratcheting up a brake until the current meets a limit right?

This would suggest with 99% duty cycle if I overload the motor with heaps of prop torque at 1000rpm I’ll just cause a very high current (beyond the 55A shown here, extrapolated? A short circuit I guess? Am I right in saying I don’t get the full 2hp until I let it run up >5000rpm?

Thanks for the help.

There is no way you are going to be able to pull anywhere close to 2hp at only 1000 motor rpms. You will need to use gearing to reduce the motor speed to your desired output speed. In general BLDC motors are most efficient at about 80% maximum rpm. Your motor is going to wildly inefficient at 1000rpm with very little torque output

Great, thanks.

I might need to rethink things and go for a planetary reduction. fun. Or bigger batteries.

what about the guys making wheel hubs, surely they go very slowly and they’re direct drive on resonably high kv motors? they’d be doing low rpm right? would they have the same issues?

So I just want to check… this is RPM at the shaft right? or is this eRPM commutations?

the 149 is a 14 pole pair motor, so that’s 5000rpm x 14 pole pairs = 70,000 eRPM/commutations. That’s a lot for a big motor and I think the vesc tops out at 70k and <60k is reccomended…

I asked because I ran my 6374-149 to 2000 shaft rpm today and it scared the shit out of me. So much metal, turning so fast it was a disaster if it seized. only 28,000 erpm.

This thread’s a bit old, but… Can you share some contact information about who you spoke with to arrange this group buy?

I’m looking to pick up a few dozen of these motors for an industrial project and I tripped on this forum post looking for better solutions for sensors, so…

Thanks

Which manufacturer did you use for this? I’m looking to order some custom motors for a project. Thanks!!

Sorry for the unattended replies:

@Leav, if you are still wondering, there aren’t any/many curves because you need a dynometer to measure these. The voltage isn’t the problem as just adding a battery or changing the power source, but the issue is having access to a dyno basically.

@brentsinger, I believe these are shaft rpm’s. That is usually how speed/torque curves are made. Input into motor and output from the shaft of motor.

[ @Dke123 @innodave ] can contact them at: [email protected]

Beautiful - Thanks!!!