I get asked this question a lot by my customers. So here is a summary of features you should look for in a deck when deciding what to buy.

There are a few important deck features to pay attention to

- Wheelbase - The distance between the trucks, Specifically the baseplate of each truck.

- Deck Flex - Does It bend/flex when you stand on it.

- Deck Shape - Concave, W Concave, Drops, Micro Drops, Rocker & Camber

So lets go through these features in more detail to understand why each aspect is important.

Wheelbase is important because it dictates the area you have available to mount your electronics. Unless you are planning to have your battery elsewhere like in your bag or pocket, which I don’t recommend as it means long cables and this has its own problems which we will discuss on another topic.

So you need space for your battery, motor controllers, motors and any other electronics gadgets that you want built in. If the deck is too short you might find it difficult to fit everything ‘on board’ that you want. This is why using a long board is so popular for building esk8. A deck of approximately 100cm is generally ample for most builds. You can definitely go smaller just make sure you calculate length of batteries, the length of your ESC & how much your motors are protruding out from your trucks.

So lets calculate it now, Motors need about 120mm of clearance. This is the area between the truck axle to the edge of your closest components housing. Unless your motors are backwards mounted which is not as common but definitely an option. If your motors are backward protruding you can have the enclosure much closer to the the trucks, as long as there is ample clearance for the truck to pivot during a turn.

You may also have other components such as on/off switches, LCD screens, watt meters. These take up some room beneath the deck. The more components you have the more wire bulk you have also. In most setups you will need to allocate about 50mm Minimum of area just for wire routing.

So for motors and wire bulk 120mm & 50mm you have already used 170mm of Wheelbase. Now the rest of the area can be used for a battery and ESC (or two ESC for dual drive)

Battery size will be directly proportional to its Wh rating. More Wh = larger battery in both weight and size. A batteries proportions can be varied. Most Lipo batteries with a decent sized capacity, say 6s with 8000mah, that you buy from the hobby store tend to be short in length but fat in height.

A 6s battery has 6 cells. Each Lipo pouch (cell) is about 9mm thick. This is fairly standard. The length can vary a lot from 130mm-200mm & Longer. The width of a lipo pouch is generally between 45mm-70mm.

As a beginner with lipo, for ease of setup normally you buy them pre-built how you want to use them. So if you want 6S you buy one. But as you get more advanced with your understanding of battery configuration you can start creating your own unique layout. For instance it is becoming increasingly popular to buy two 3S packs, which are about 28mm in height (instead of 60mm like a 6s) and wiring them together in serial or parallel to get your desired voltage or capacity. The slimmer battery configuration allows for improved ground clearance, which is very important, but requires more real estate (both length & width) beneath the deck to lay the batteries out.

So if you are going to customize your Lipo packs for the slimline look & maximise your ground clearance you might end up with two batteries end-to-end OR side-by-side.

The battery therefore could require up to 400mm in deck area!!.

The ESC will generally require about 100mm maybe slightly more if you have lots of wire bulk.

This is another nice way of using the space efficiently

So for the slimline look using 3S Lipo you probably need max of 670mm long wheelbase. If you mount the batteries side-by-side maybe you will need just 470mm of area.

Deck Flex as you can already imagine will be a problem if you have a really long battery, current battery technology isn’t designed to bend.

What is Flex - This is the bouncy feel that you experience on your longboard. Flexible longboards are best suited for low speed riding. longboard decks can come in a variety of flex patterns including (but not limited to): Light, Medium, and Stiff. Flex may be indicated numerically or indicated in the description of your longboard deck. A flexible longboard deck will soften the ride on rough concrete and over bumps and cracks but will be much harder to use when building an electric skateboard.

However there are ways of getting around the bending issue.

- Don’t mount solid parts where the deck flexes, so this generally means avoiding the middle section. Put the battery behind the front truck and the the ESC at the other end with wire spanning the gap. It actually works fairly well as the wires across the middle actually don’t bend much so this technique is viable. However much more challenging to make it look nice.

Here is a custom made board I built for a customer last year that uses this mounting method.

-

Run you battery array sideways down the board, as pictured above with four 3S batteries side-by-side, if each battery is separate they will move independently when the deck bends. I tend to think this will result in some additional cost & maintenance though as wires & solder joint may eventually break due to constant bending & flexing. You also need a flexible enclosure. I have often though of using some kind of silicone like they use to make mobile phone protective shell cases with.

-

Put your components elsewhere… like in your bag… I really don’t like this idea. I think everything should be safe & secure built into the deck, or in a hard case beneath the deck, its not just for personal safety but also to protect your expensive components from the harsh environment.

So if you do decide you must have the bendy one, make sure your mount the components onto the deck in a way that allows the flex. Plastic or Aluminium enclosures won’t flex like the wood does. The surface area beneath the deck expands as it flexes, this will put force onto the screws, glue or what ever you used to attach your enclosure. It may also break your case.

The other thing to consider about decks that flex is at high speed they are not as responsive as a solid deck. So if you plan to travel at high speed, which I tend to think is anything over about 30km/h, you don’t want a flexy deck. What you want is a rock solid unit that responds to the most subtle flexion in your ankle to help you navigate the unpredictable streets that you ride on.

30km/h is 8 meters per second. Just think about it.

its worth noting that when it comes to decks that flex or bend it wont be the same for all riders. Your body weight will determine how much flex occurs. So if possible I suggest heading into your local board store and trying the deck out.

So to summarise, I would generally avoid the flexy decks!.

Deck Shapes will present the e board builder with various challenges.

Concave - The curvature between the two sides (left-to-right) of the board. Concave helps hold your toe and heel in place, giving the rider more control of the longboard. Concave locks your feet into your longboard deck while carving in and out of turns. When build an electric skateboard on a deck with a lot of concave you want to avoid having a wide component housing, as it won’t sit flush beneath the deck. Long & skinny is better.

Camber - The amount of upward bend along the length of a longboard between the two trucks. Because of camber, the riding platform is set higher than the truck mounts. Camber allows the rider to have more leverage for turns while riding the longboard. On more flexible longboards, camber ensures that the rider will sit at the same level with the trucks (rather than below them). Also, camber allows for boards to have a lot of flex without letting the deck touch the ground unexpectedly. Boosted boards made a really nice electric skateboard using a flexible deck with camber so its not impossible, but it just means you need to split the components apart, which adds to the cost of the build and complicates the build. It also lengthens the battery wires which can be a problem for some ESC.

Rocker - The longboard deck bends downward in a smooth arc (like a banana) so that the center of the board is below the trucks. Because of this arc, the nose and tail are “wedged”, allowing more turning in the front and rear trucks. Rocker is good for long distance pushing since now the deck is lower to the ground. This is also known to make for a comfortable freeride deck since it decreases the stress on your knees and ankles. These should be avoided as you don’t want your expensive electronic stuff grinding across the ground.

“W” Concave - This is the concave that takes the shape of a “W” in your standing platform. The bump created is also referred to as a “dome”. This “dome” fits the arches of your feet giving you more control with your back foot. This can work really good for your eSk8, However the “W” profile will generally mean that the underside of the deck is not flat so mounting can be a problem. You will definitely need to screw or bolt your enclosure onto the deck, double sided tap won’t work as the mounting surface is not flat.

Drop Deck - This form of longboard deck involves an effective foot platform that is dropped to sit significantly below the truck level. The main advantage of the drop platform is that it can be lowered to barely clear the surface, although the actual deck height ultimately depends on the size of the wheels. The lower center of gravity creates more stability and causes less stress on the knees and lower back. These decks can work! But you need really slim components or large diameter wheels, probably both.

I used this type of drop deck, the Bustin ibach 40", for the custom made enertion all-terrain decks that I made.

These are some of my favourite decks that i have converted into eboards. Super Glider by Earthwing, this deck is super light & really flat across the underside. I personally love having a kick for extra manoeuvrability & popping down gutters or over cracks, In my opinion this is Probably the perfect eboard deck…

Machine by JET, Not the easiest deck to mount electronics onto, but the shape is just so awesome, it has a slight micro drop but nothing you can’t easily overcome with some planning.

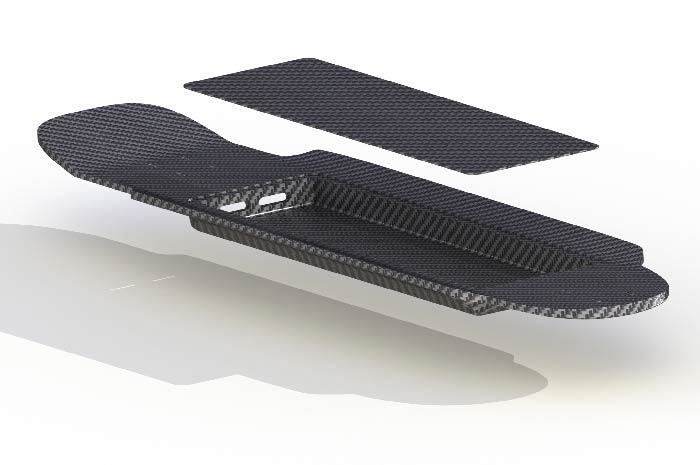

THE FUTURE DECKS FOR EBOARD BUILDING I believe that eventually people will want decks that are custom made & specifically designed for eboard builders. Carbon fiber is probably the best material to use as it is very strong & light weight.

This is the all-in-one carbon fiber eboard deck deck I will be using to make my next electric skateboard with in a few weeks, once it comes out of production. For the design I took inspiration from the Earthwing Superglider it has a built-in cavity for the electric components so the result is a super slim & rigid deck perfect for high speed & high performance.

At the end of the day what’s most important is you have a choice! You can decide what deck you like based on your weight & your vision of what the perfect eboard should be. Choosing your own deck is the reason that building your own electric skateboard will always be better then buying one off the shelf. Everyone is different and everyone deserves a choice.

I just don’t have a battery to fit within that spec size. You have any extras in-case I do change my mind?

I just don’t have a battery to fit within that spec size. You have any extras in-case I do change my mind?