Over the past 6 months I have finally managed to cobble together a carbon fiber enclosure.

To start this off, during the summer I put together a CAD/CAM of what I wanted it to look like. Then to build the mold plug I laminated two MDF sheets together and cut it out on a 3d router.

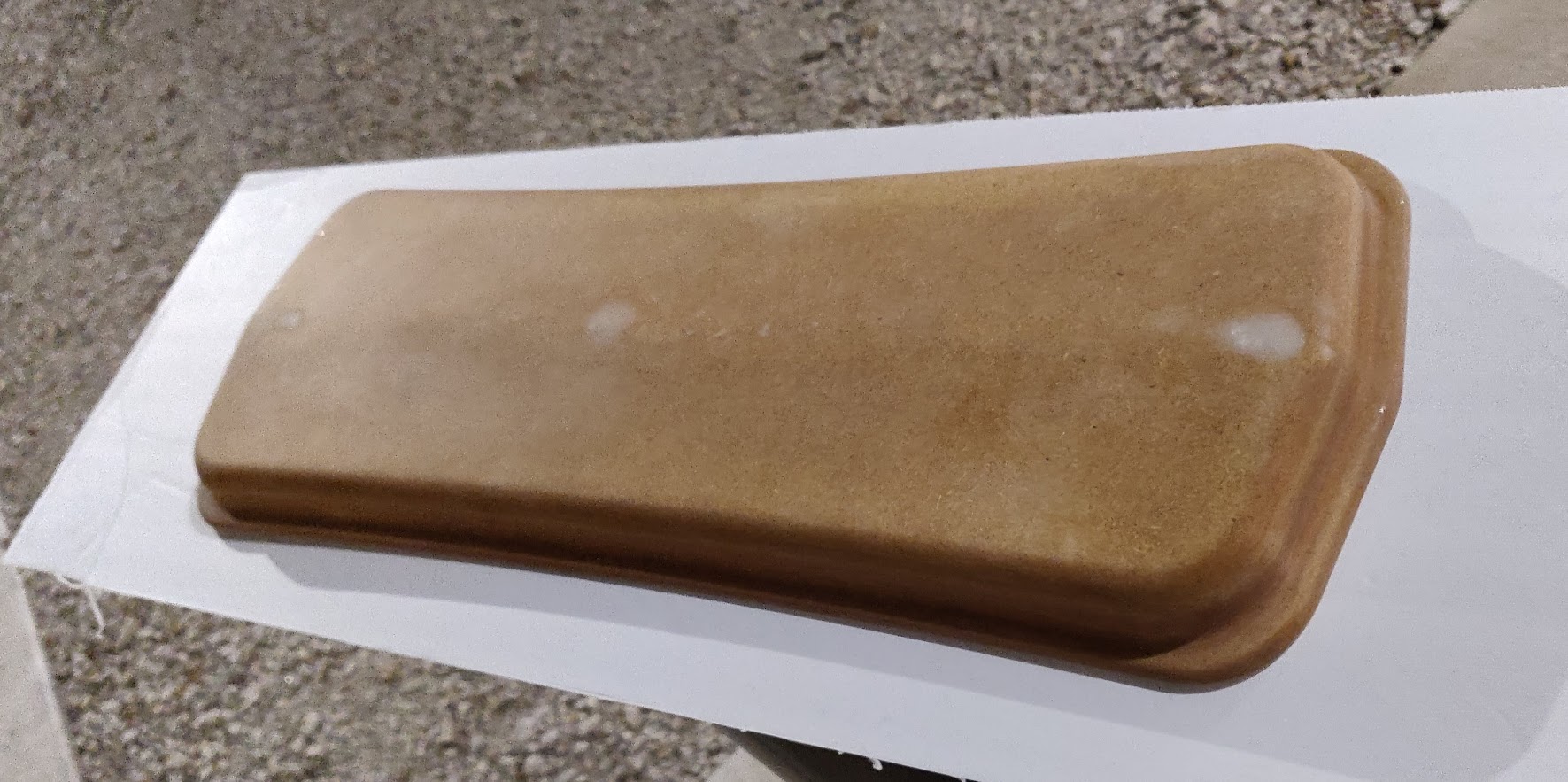

The resulting plug was fairly rough and had a fuzzy finish due to the MDF particles, after a few hours of rough sanding and a coat of epoxy I was then able to sand it down to a smooth finish.

After probably 40 hours of sanding, coating, sanding, painting, sanding, painting, polishing, and waxing it looked pretty good.

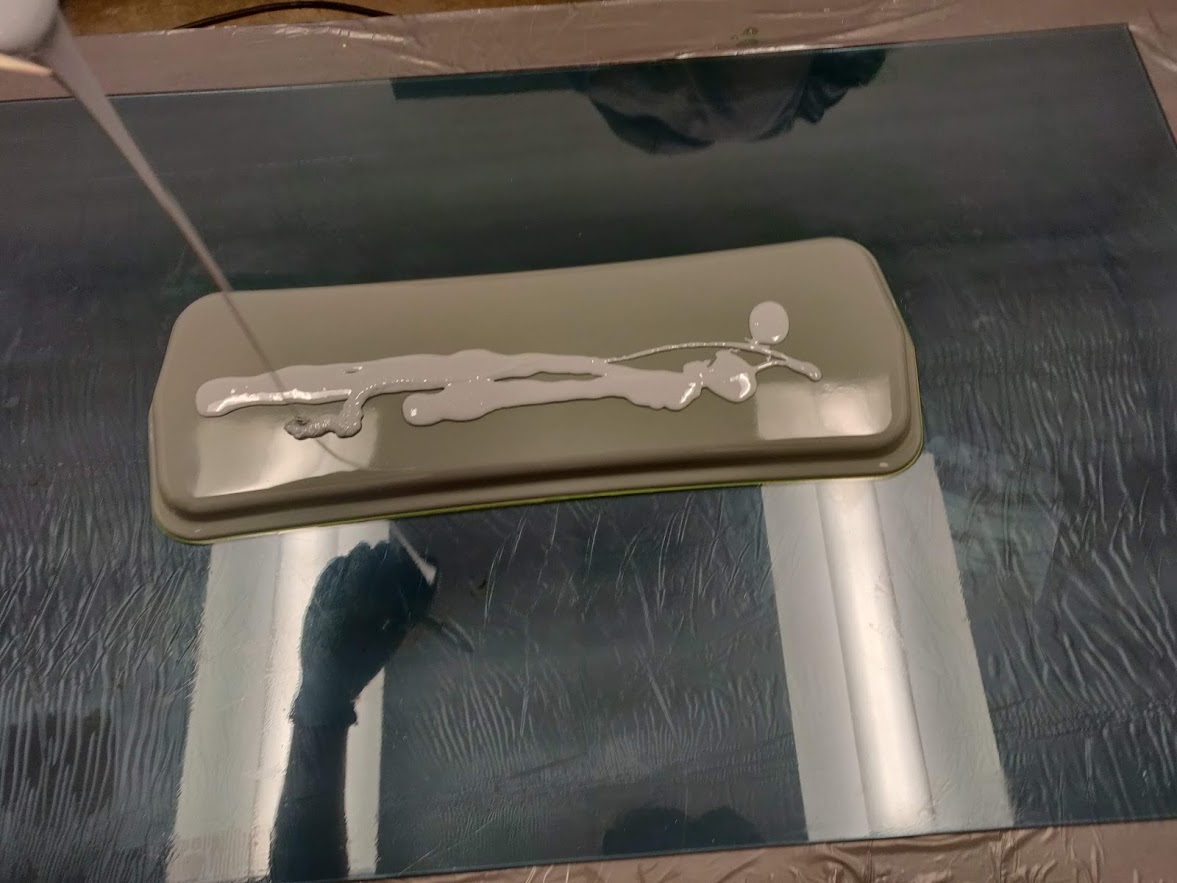

Due to school starting back up I had to take a 5 month hiatus on the project, then last week I was finally able to pick back up on this project. So commenced the mold making process.

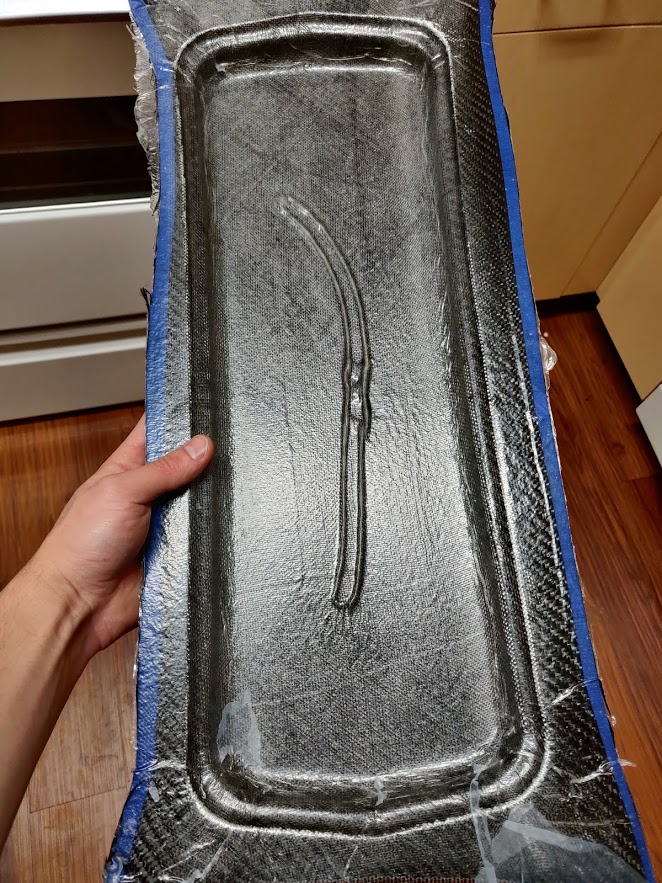

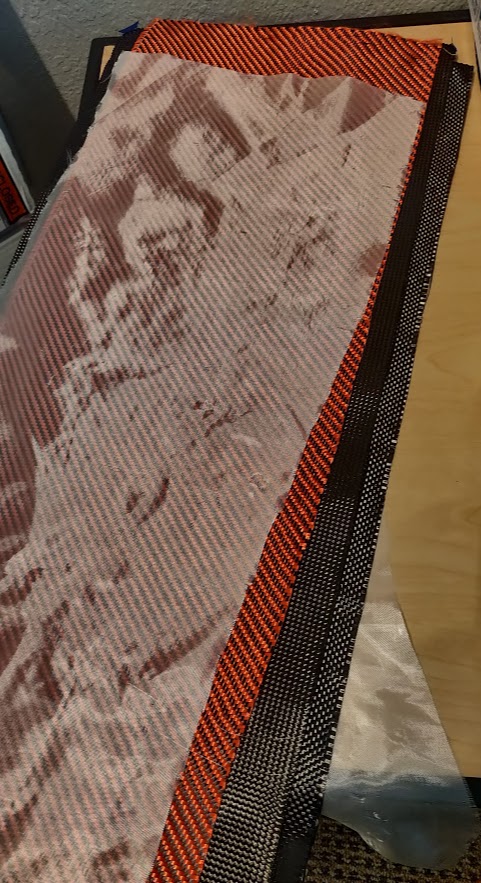

!This was the first time I have messed with infusion layups so it has been quite the learning experience, I think the radii of curves on the mold are too small for infusion, as the stiff infusion mesh was unable to properly conform to the mold under vacuum and once I began infusing the resin a vacuum leak appeared in the bag which I was unable to find.

Using expired west systems WB-400 resin and CS-215 slow hardener, there was no issue wetting out the entire part. However, because the fabric could not fully conform to the mold a slight gap was left around the corners and when the vacuum leak developed, air was sucked into the voids in the corners of the mold leaving some unsightly bubbles in the surface finish.

For an experimental first attempt at infusion, I can’t really complain about the results. For the next few enclosures I am going to do a traditional wet layup using sheets of prepreg fiber, might put down a clear gelcoat layer and let it tack over before laying down the first layer to insure it will properly conform to the mold.

Was it worth all the effort? If analyzing the time and cost of it, definitely not. However I do this for the heck of it, to learn, and so I can say I did it, so I consider all the extra effort to be worthwhile.