Why is the shank length 4x the threaded length? Sure if it’s a 100% threaded bolt it’s gona take a lot longer to tighten but would you rather more time spent assembling or munching on concrete!!

You’re only seeing a small portion of the threads in my pic (maybe why everyone assumes I didn’t apply loctite correctly?). It’s actually like 50/50 threaded vs not.

For such an essential part it should be 100% threaded and BTW just FYI loctite 277 high strengh I highly recommend all my nuts and bolt have never come loose using this.

Yup! And then a heat gun releases it easily. Isn’t heat an issue in hubmotors?

Mike, Just occurred to me that I use heat to release loctite. Loctite isn’t the answer here.

The loctite I use requires temperatures in excess of 450゚ to release, if your motors are that hot they’re done anyway.

450+ !! What type/brand do you use. I like that!! Regular Loctite is 300F, which is probably hot enough!! Hot enough to cook a chicken on it. LOL

It is, even hummies little motors with all of my abuse and miles on miles of aggressive hill riding, never got above 270 F

All though now, I’m rewinding these guys with 392 F windings, as I do get them to 250 F by the end of my commute to my university. They were likely cheap shitty quality wire before. Another benifit to the new design, since they will be assembled here in SF.

I use red 272 and it breaks loose with a tiny little heat gun…Again, Ratings are shit. Relying on loctite so that you don’t street your face when a bolt backs out the wrong way is ridiculous… This is a horrible case of “Safety First Unless it Costs More Money”

I currently use the Loctite Semi-Permanent blue for my screws on my board. Only put in 10> miles so far but it came a little bit loose after the first 5. I tightened it up and it hasn’t shown a problem since.

Would you recommend the red 272 instead?

272 is specifically designed for for high heat.

@psychotiller I use my soldering iron at 480 to release my fasteners. How do u usually apply the heat break them free?

Have u had any come loose without intentional heating?

I just hold my heat gun to my mounts or screws that I need to break free. And the amount of time it takes, I’m positive its not getting to 300°

And no to your question. But a bolt falling out of my mounts isn’t going to seize anything.

I think what Im really getting at here is that there will always be drawbacks to the various designs out there. With hubs, we currently have slipping urathane, loosening bolts, rough ride from thin or hard urathane, motor cans exposed to debris, overheating, etc. I had the same issue where the metal rods in Jacob hubs with the ralphy 100mm mod moved inwards and tore my phase wires clean off which fried a VESC X. I informed him and he immediately offered a refund. I didnt accept the refund because I personally feel that I should take on a certain amount of personal responsibility for buying and using newly designed and experimental parts in an inherently dangerous sport. This is my personal stance and I can respect others opinion on this as well. I just want to make sure that the hub motor innovators in this industry like Dexter, Jason, Jerry and Hummie can keep bringing new and improved versions of their product without fear of retribution. I have yet to see a new version of hubs that wasnt substantially better than the last. I have also not seen a new version that solves all the typical issues but they sure are getting close. Just my two cents. Cheers

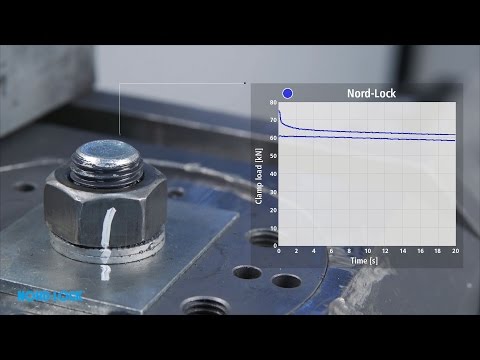

I just thought I’d throw out Nord-Lock Wedge locking washers. Because friction is NOT a reliable locking method.

You motorcycle guys out there def need to check these out…Nice, the only issue I can think of with washers is you might need slightly longer bolts to get the same thread depth. Theres always the saftey wire method as well. I actually used it in the urathane retaining ring of Dexters 1st version of hubs  .

.

For sure! Good excuse to upgrade the bolts as well. Maybe some nice Grade 8 steel ones!! @BigBoyToys So you actually did safety wire!? Respect! That can be a pain in the ass to get done. Lot of work…Throw up a pic, bro! That sounds pretty killer.

You could be right. I tend to over due stuff (said bullet proof  so I use red locktite in most stuff.

so I use red locktite in most stuff.

Here is the safety wired version of dexters 1st hubs. His new version totally solved this problem so no need to do this again.

That is SICK!!