What’s the best gauge and strand count that you would suggest for the stators, I’m sure I can help ppl get some wound up. Probably only $40 per stator and the stators should easy to replace as I got the factory to use c-clips and a key way. There might be some epoxy.but if most ppl are happy with 30a current then the original winding should be fine.

Yeah, 40-60Amps is stretching 21 Awg equiv.

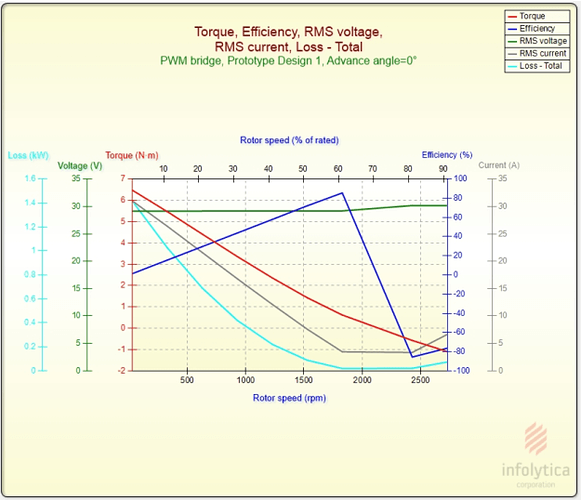

Efficiency drops above and below 14-17 gauge. It’ll keep the stator pretty cool at 10s 30-40Amps 60min max torque @ max speed gives me a heat increase of about 125°C from room temp (see second graph, third range). This assumes the motor is fully sealed. Jacob’s design does have some air cooling potential.

I’m not giving away months of simulation and multivariable assessments for free, but I’d suggest starting your work from those gauges as a continuation of your work. Side by Side vs Overlapping, Delta vs Star, and Lap vs Concentric winding will give be good conditions to start from (try to get as sinusoidal of a waveform as you can). Turns and what gauges to combine to get the right total gauge will take you time (hint phase resistance matters a lot more than you might realize). It’s not linear so don’t treat it as such because you’ll go crazy. ALSO - don’t discount eddy losses. You don’t need 100% copper fill. Trust me.

With two of my motors, you could push a 220 lbs person up a 25% grade at full speed (2250 rpm = 25mph). Each motor has a near perfect sinusoidal BEMF. I am working on finalizing the design before I do a prototype run. I keep finding that I’m able to squeeze a few more Nm of torque every couple weeks.

NOTES:

- Simulations are using Current Hysteresis PWM

- I’m half way through programming a dsPIC based ESC

- None of this is for sale, public beta testing, or sharing because no company I have worked with will respect any NDA and I don’t trust people enough anymore after I almost got backstabbed by a USA prototyping firm.

Jacob’s design is good as a pure hub motor. It just needs some refining that requires both time and motor design background. I would suggest that if you guys are interested in rewinding stators, you should just make a group order for a handful. Its gonna cost you about $50-70/unit in a set of 10 (basically $600-800 when you factor in shipping) - DON’T HAVE THE FACTORY WIND THEM. You should limit yourself to no more than 5mm end winding length, otherwise debris become an issue.

Proof that it can be done at 35 Amps for almost double current design torque:

Proof of Thermals:

Correction: I accidentally stated that these were from SVM simulations. While the statement, “SVM is wonderful and can be very quiet if matched up with a well built motor” is true, these were performed with PWM Hysteresis (Sorry, the two projects literally share the same name except for the SVM/HYST tag).

What is the original gauge and strand count? Delta or Star?

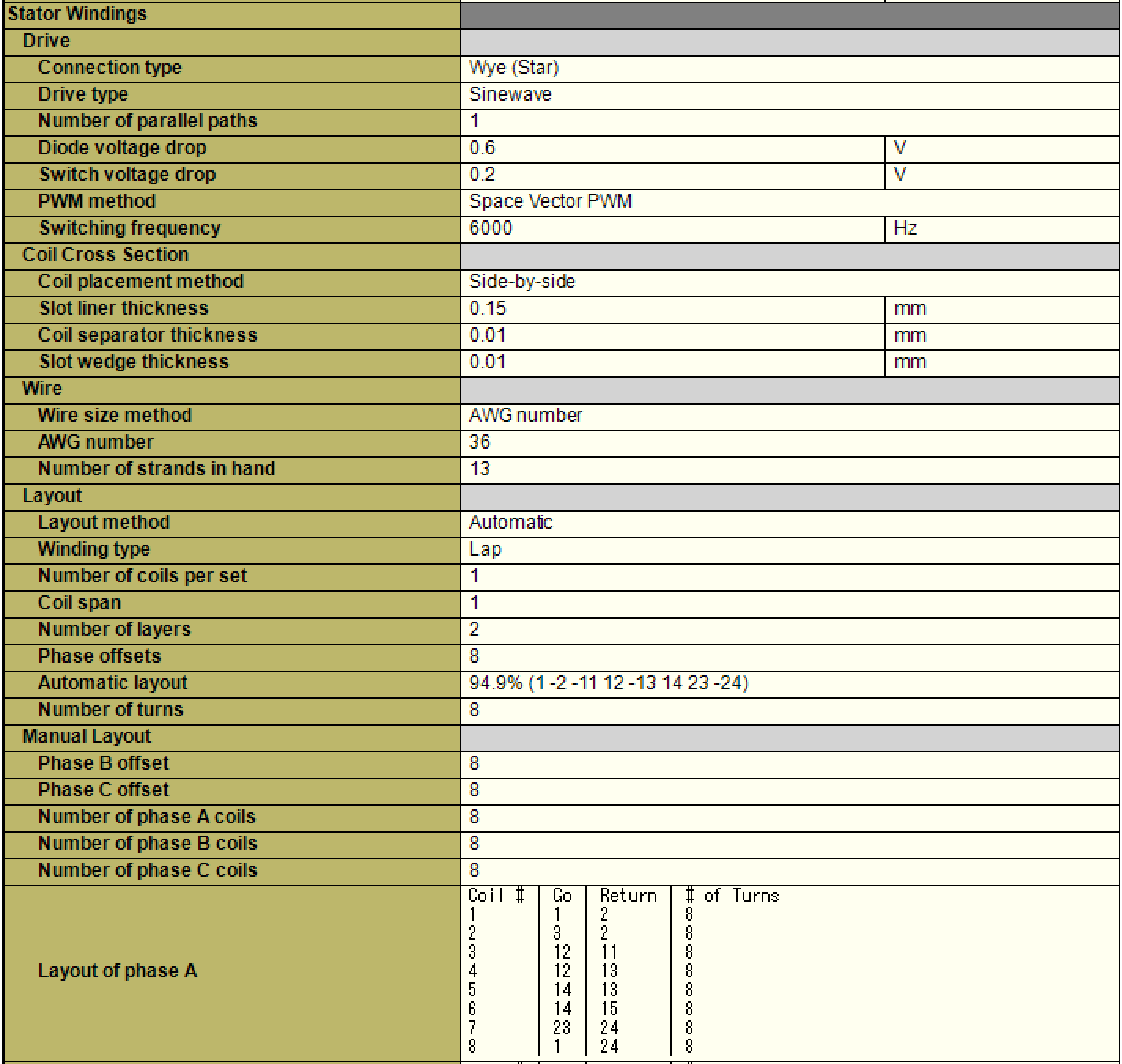

It is wye:

thanks, wye is star and who knows more about the original winding. In the moment I’m happy with the original winding but if problems occur and have to rewind the stators it would be good to know the original and start from there.

0.19mm (36 gage) wire, I personally hated this wire but the factory wouldn’t use a different copper and it was hard to get a factory to do what I wanted to do in the first place. The strand count should be between 18 and 23. Depending. The turn count in Wye to get about 65-75kv is about 8 turns. This can change depending on magnet fill EMF leakage ect. It gives a huge resistance in wye if my calculations are correct 480mohm A delta winding can more then half the resistance. But I personally found that Wye was great for these motors.

Using a 0.8mm (21 gage) wire in Wye you could maybe get 2 strands at 8 turns your resistance will be about a third of the 0.19mm copper at about 180mohm. If you use a delta winding with 16 turn with again 0.8mm but now only 1 strand the resistance is about the same but the current allowance will not change much because the copper cross section has halfed.

I probably haven’t done as much simulation based testing as @anon94428844 bit at 16 gage I can’t see my self getting more then 3 turns of single strand in that stator getting a 180kv in Wye.

You could get 7-8 turns of 19 gage single strand in the stator but I would be worried about my phase wire snapping constantly.

True stuff. I said gauge equivalent though, so I’m using the thickest-thin wire/more strands for the least resistance.

I have a delta and a wye model and they’re wound very differently. I found that there is a real struggle to balance the speed and torque between them just by adjusting the winding simulations. It’s pretty fun actually when you get into it.

I’ve been largely ignoring the calculated kV since it doesn’t tell me enough. I keep an eye on torque and temp more than anything else.

Thank you so much, this will help a lot when I have to rewind it one day!

I believe this is an accurate reconstruction:

6Khz SVM Freq.

20Khz SVM Freq.Winding Specs

Reference:

Torque for 80mm Wheel to stall/equal to gravity: 05% - 3.9Nm total 10% - 7.8Nm total 15% - 12Nm total 20% - 15Nm total 25% - 19Nm total

RPM/Speed for 80mm Wheel: 0560 - 05 mph / 8.1 kmh 1100 - 10 mph / 16 kmh 1600 - 15 mph / 24 kmh 2100 - 20 mph / 32 kmh 2700 - 25 mph / 40 kmh

Notes

I cannot accurately simulate the temperatures with a SVM driven motor. Based on our findings however, I would say that they’re problematically high on long trips. I don’t know what the VESCs default switching frequency is so I’m including a 6 and 20 Khz Simulation. It looks pretty accurate though.

Jacob wrote “strand count should be between 18 and 23”, in your chart you wrote “Number of strands in hand - 13”. So how many strands are really used in the original winding?

I had 15ish.

I think I settled on 18

Hi, wie teuer war denn das Gesamtpaket? Also mit Steuern und Versand? Momentan gibt es das kit für 255$ + 35$ Versand = 290$ zu kaufen. Ich würde nur gerne wissen was du an Steuern zahlen musstest. Ach ja, ich habe gelesen, dass die Motoren am besten mit einer 6-12s Batterie angetrieben werden sollen. Weist du wie viel Ampere die ziehen? Ich war der Ansicht gelesen zu haben, dass einer 30A zieht aber naja… Dank schonmal im Vorraus

Nice one. Could you tell me the Ampere which the motor will ‘use’? And will a 6s setup work as fine? Sry for my English btw

Hey @jacobbloy - its a long thread and I may have missed something - did you send out anything for the remote control project. I singed up for the “i’ll put it together group” - just checking in

No one else needs the plastic sleeves and inserts to stop the slipping wheels? I sold 2 orders only.

International shipping kills it for me… i’ll probably go the “drill a big hole into a wheel” route

Yeah - not gonna spend money on 3D printed parts that need to be shipped internationally when I could just print them myself.

I printed mine with 0.09mm or 90 micron layers it’s so thin that there is no need to worry about infill % just make sure your wall thickness are more then 3 layers. I am testing printing one with 0.14mm layers as most will have a similar resolution on there printers. And printing 2 on the same bed.